Creating Healing Spaces

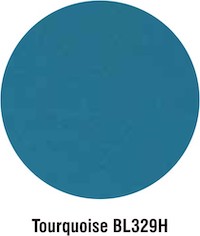

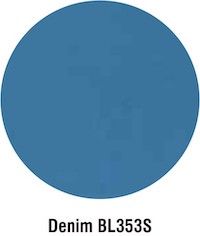

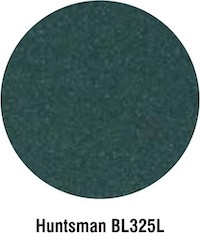

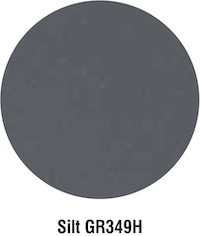

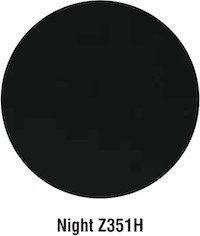

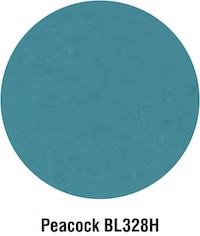

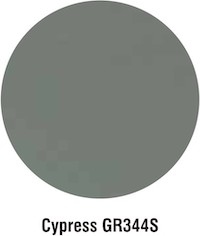

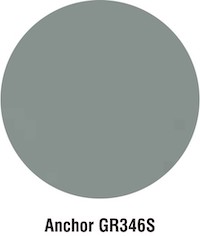

Corques Liquid Lino Fluid Applied Seamless Resilient Flooring

REQUEST SAMPLES

* Samples are free for the local Alberta architectural and design community. If you are out of Alberta please fill out the form and a qualified Sales Representative will contact you to discuss your project.

* Currently, not accepting any residential homeowner requests.